Liquid level converted to Flow by Industrial Edge Router for Parshall flume flow measurement

Liquid level converted to Flow by

Industrial Edge Router for Parshall flume flow measurement

Introduction

Parshall flume is an open channel flow metering device that was developed to measure the flow of surface waters and irrigation flows. Widely used in urban water supply diversion channels, thermal power plant cooling water diversion and drainage channels, sewage treatment inflow and discharge channels, industrial and mining enterprise wastewater discharge, and channels for water conservancy projects and agricultural irrigation.

Principle

Parshall flume is a special flow measurement method, to collect its data need to be calculated by the formula to identify. The traditional method is to collect flow data and calculation through totalizer and PLC, and then transmit it to the water monitoring center through 4G DTU or 4G industrial router. This method is expensive and difficult to maintain. For smart water conservancy and water engineering personnel, they are helpless.

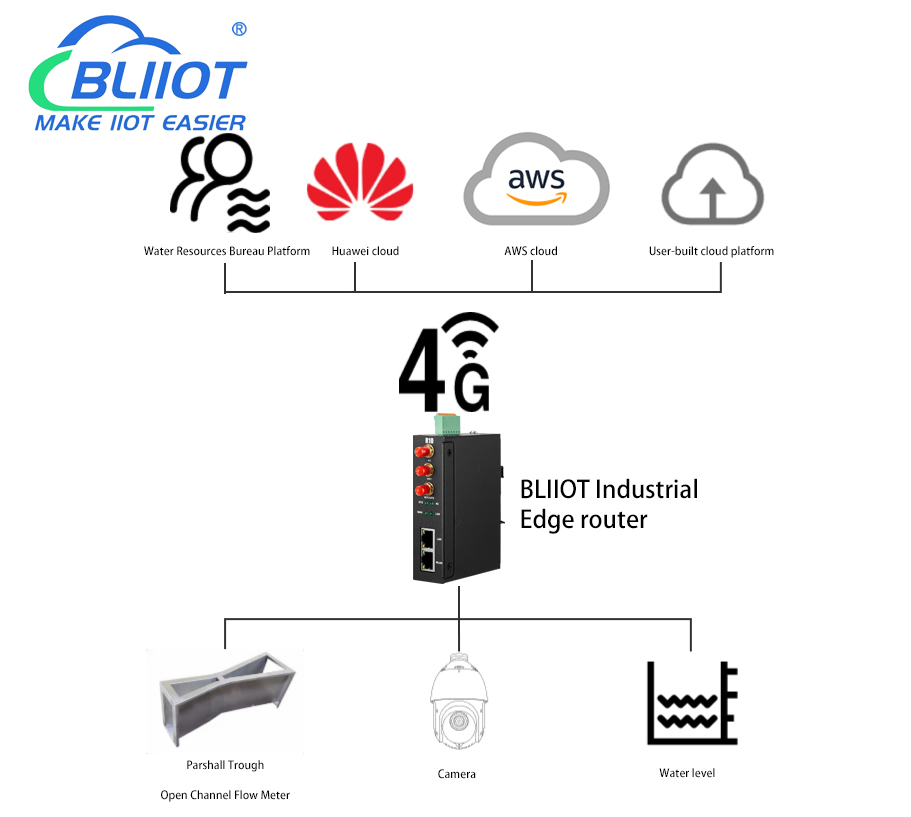

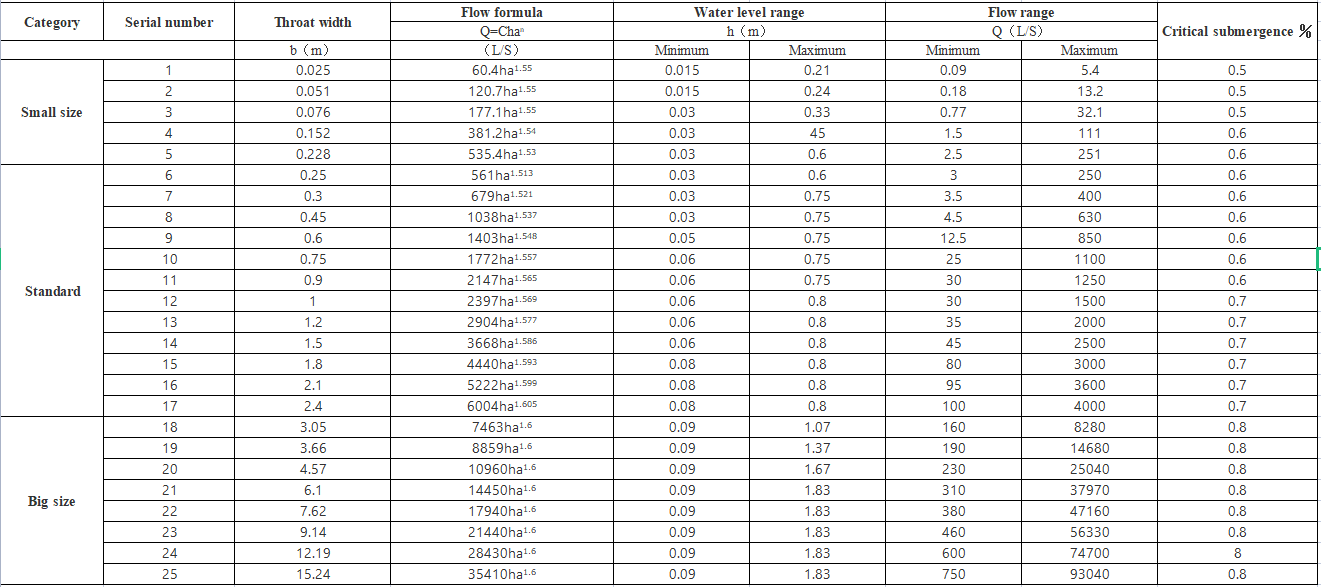

On an occasional opportunity, an engineer of a water conservancy construction project in the northwest region reported this situation to the personnel of the BeiLai technology marketing department. After a long period of communication and understanding, they finally jointly developed a 4G wireless smart water conservancy industrial edge router. It is capable of video acquisition, Parshall flume data acquisition and calculation of open channel flow meter, and protocol conversion into MQTT protocol. This not only reduces the cost by 1/3 of the original, but it is also more convenient, and can also realize remote logic control, which reduces the data storage pressure and development difficulty of the monitoring center.

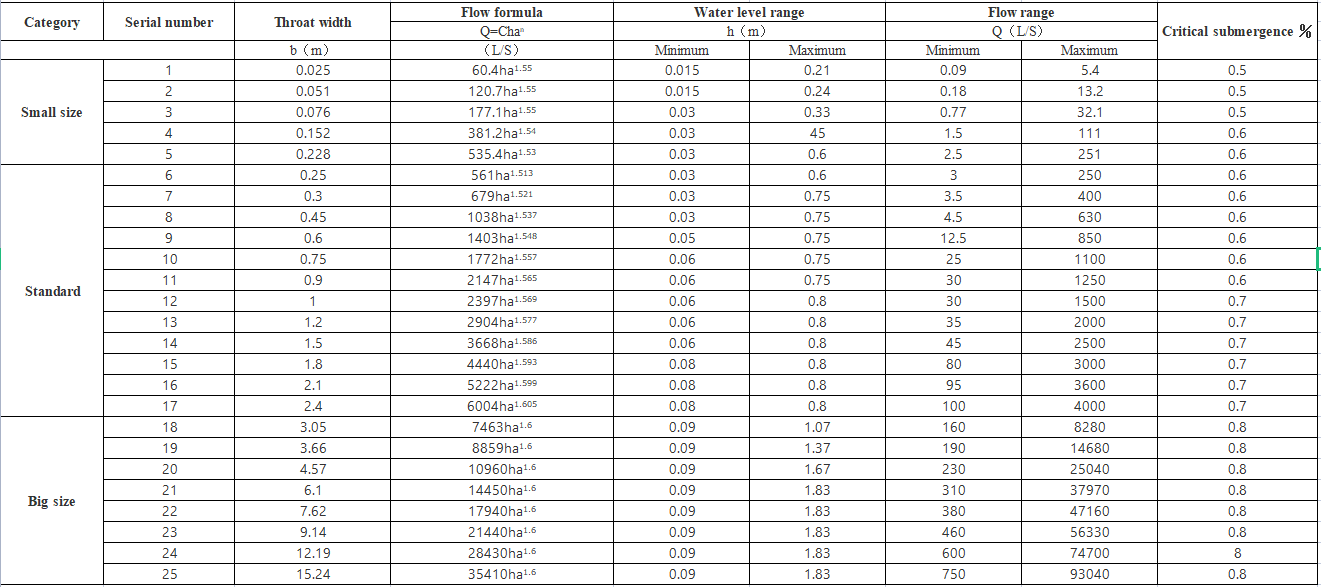

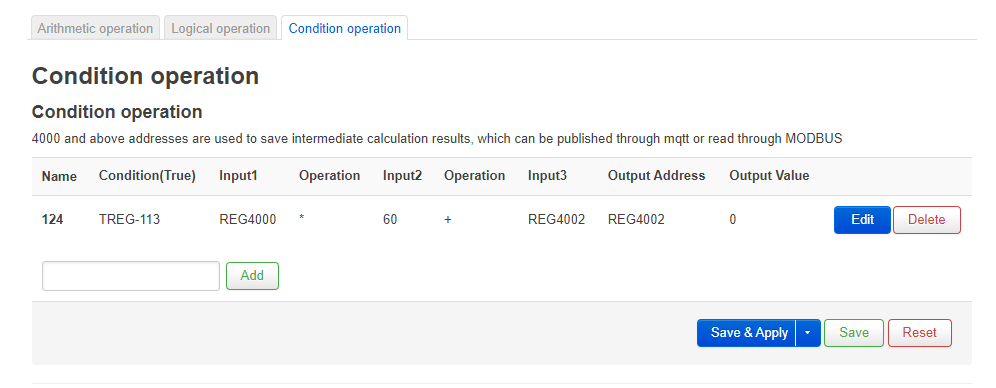

Parshall flume calculation

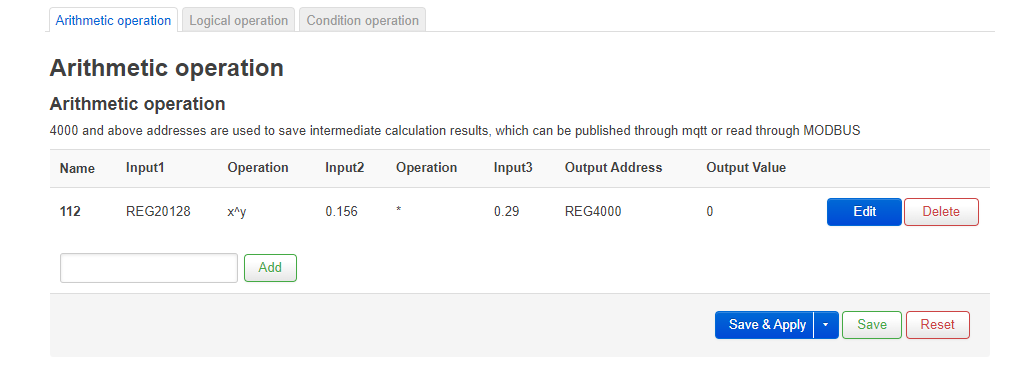

Parshall flume calculation formula Q=CH

n, the larger the flow in the open channel, the higher the liquid level; the smaller the flow, the lower the liquid level. For general channels, there is no definite correspondence between liquid level and flow. Because of the same water depth, the size of the flow is also related to the cross-sectional area, slope and roughness of the channel. Install the weir groove in the channel, because the gap of the weir or the constriction of the groove is smaller than the cross-sectional area of the channel, the corresponding relationship between the upstream water level and the flow rate of the channel mainly depends on the geometric size of the weir groove. The same weir tank is placed on different channels, and the same liquid level corresponds to the same flow. The weir tank converts flow into level. By measuring the liquid level of the water flow in the water weir tank, and then according to the relationship between the water level and the flow rate of the corresponding water weir tank, the flow rate can be calculated inversely.

Traditional way is to use an integrator or PLC to convert the liquid level of the Parshall flume into flow. If remote monitoring of data is required, a wireless transmission gateway must be added. Now users only need one R10A to complete the liquid level to flow. It can also report the collected data to the platform through MQTT, and the R10A can also provide network access for on-site cameras, which greatly reduces the cost of users.

System Introduction

The

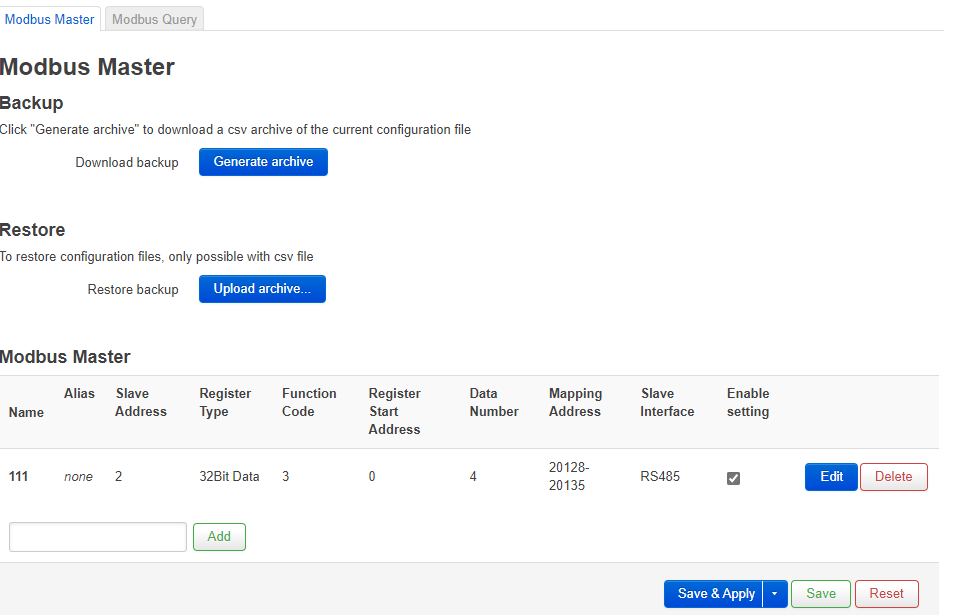

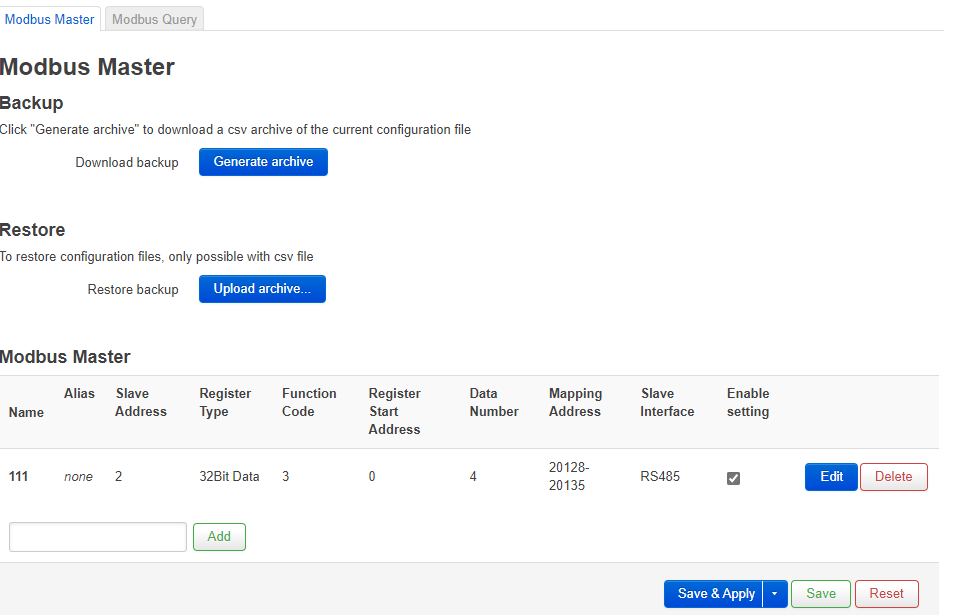

BLIIOT R10A industrial edge router has an RS485 port that can collect the liquid level status of the Parshall flume, and also provides a network port to provide a network transmission channel for cameras and other network devices on site! R10A collects the liquid level data of the Parshall flume and converts it into a flow formula through the built-in Parshall flume liquid level. Users only need to select the model corresponding to No. 1-25 in the gateway configuration software, and the gateway can calculate the instantaneous flow.

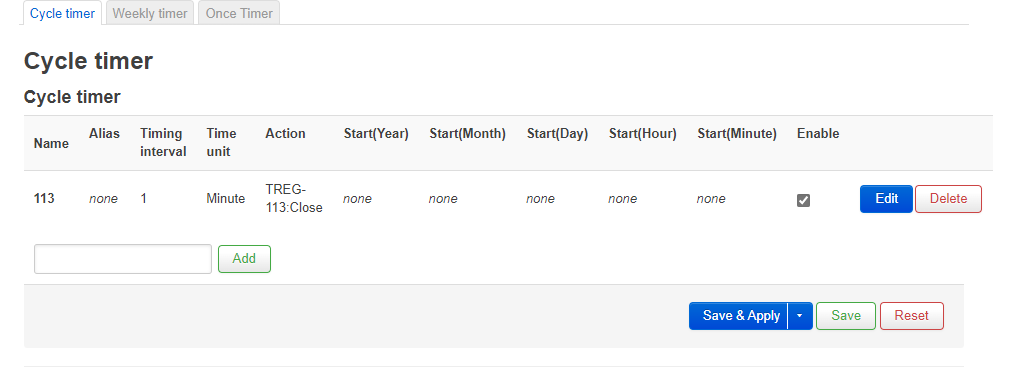

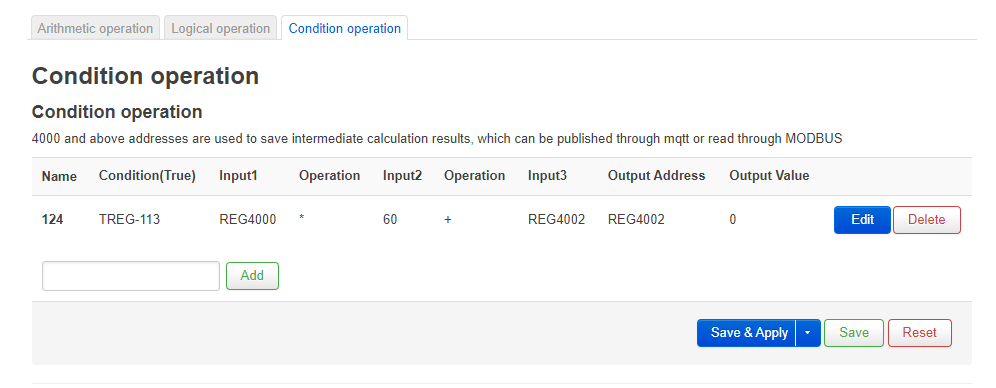

It can also accumulate the instantaneous traffic, and then upload the data to the cloud platform through 4G or WiFi, MQTT protocol. Compared with the traditional solution, one PLC or Totalizer is reduced, and the cost is reduced by at least 50%.

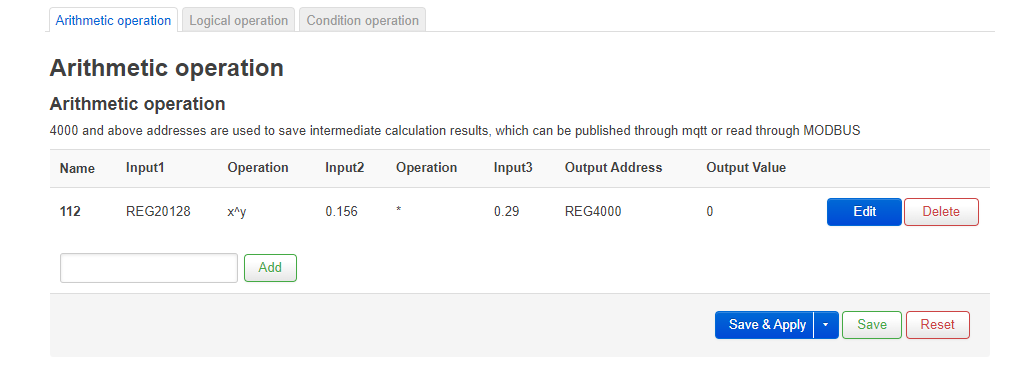

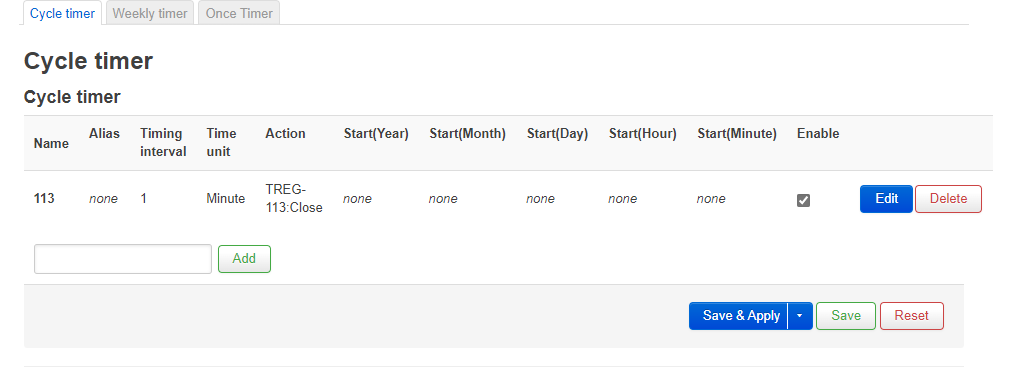

Similarly, R10A has updated the conditional operation function and numerical accumulation function. Through the conditional operation function, the user can perform addition, subtraction, multiplication, division and power operations on the registers collected by the data. With this function, the user can perform some more complex formulas operation. Through the value accumulation function, users can regularly accumulate the value of the register according to their own needs. For example, the instantaneous flow of the flow meter is accumulated once per second to become the accumulated flow.

With its powerful functions and stable performance, R10A is very suitable for data collection of Parshall flume liquid level and flow! The industrial-grade design can run stably in the Desert!

Message

If you have any suggestions or question for us.Please contact us.